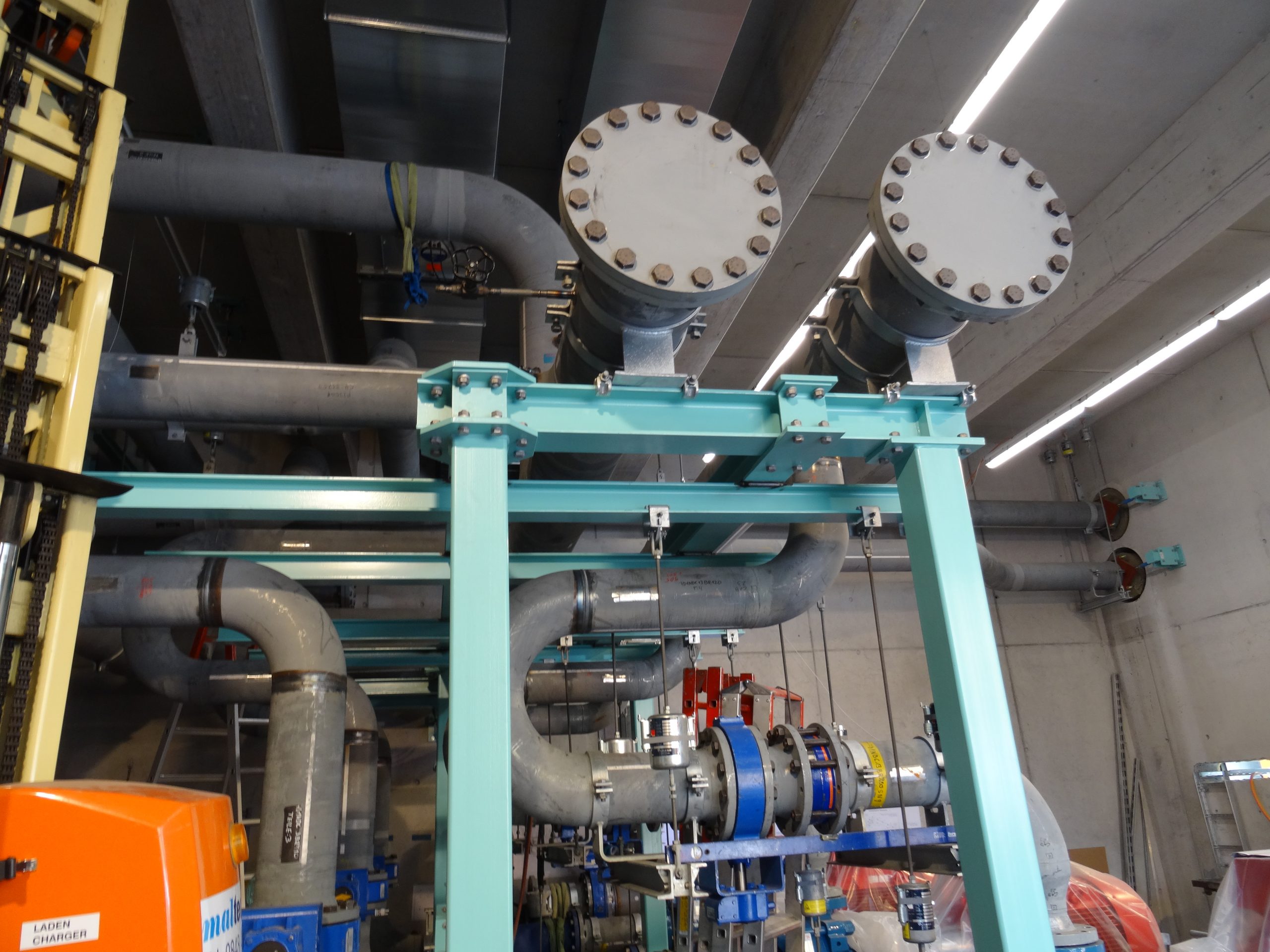

Durable Support Systems for Industrial Applications

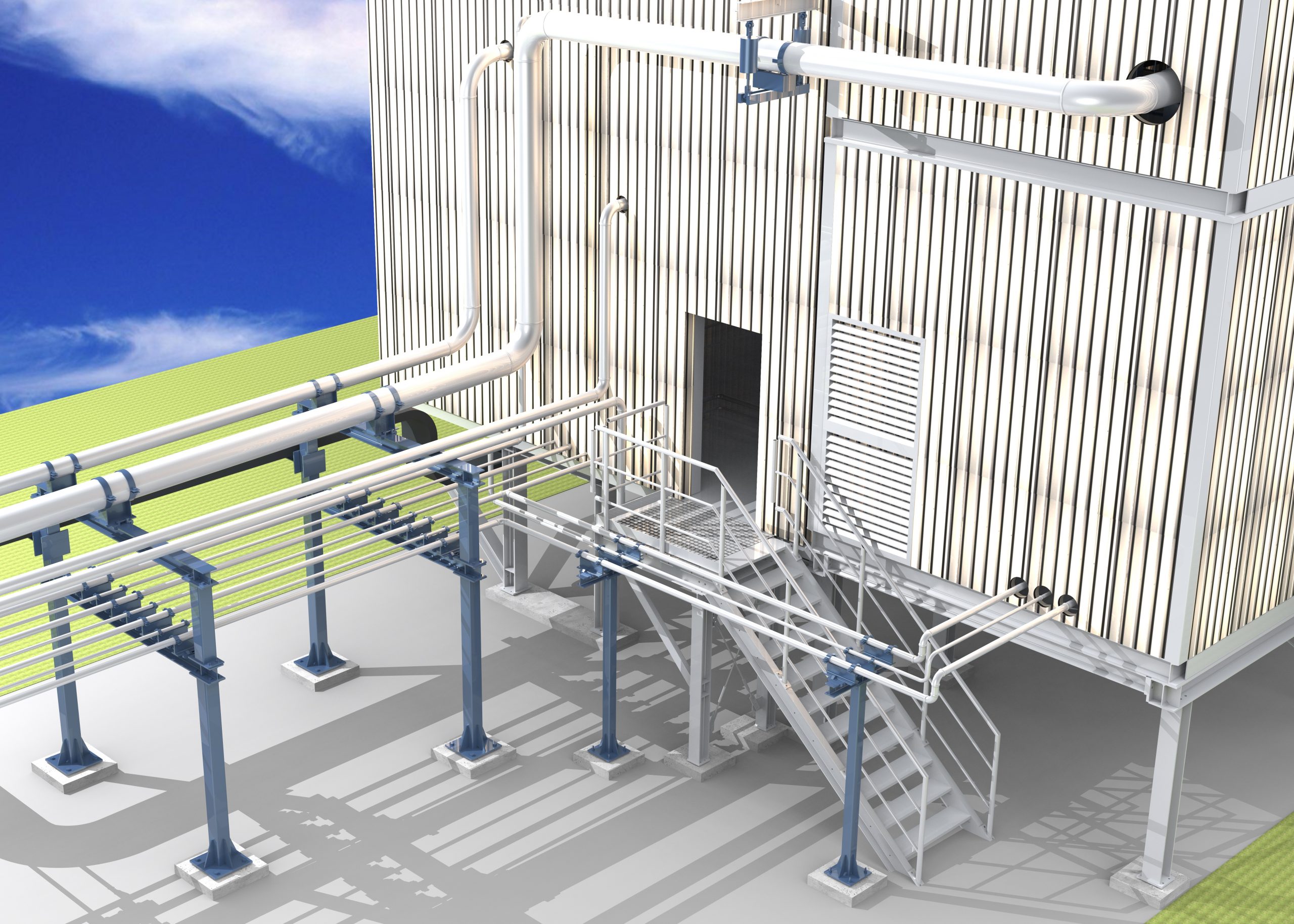

Our customised modular support system for industrial piping and components is an innovative solution for reducing costs and shortening deadlines in plant construction and building installation – from planning to assembly.

MP-FLEX

The MPSS support system offers the solution in forward-looking pipeline construction and for every support application.

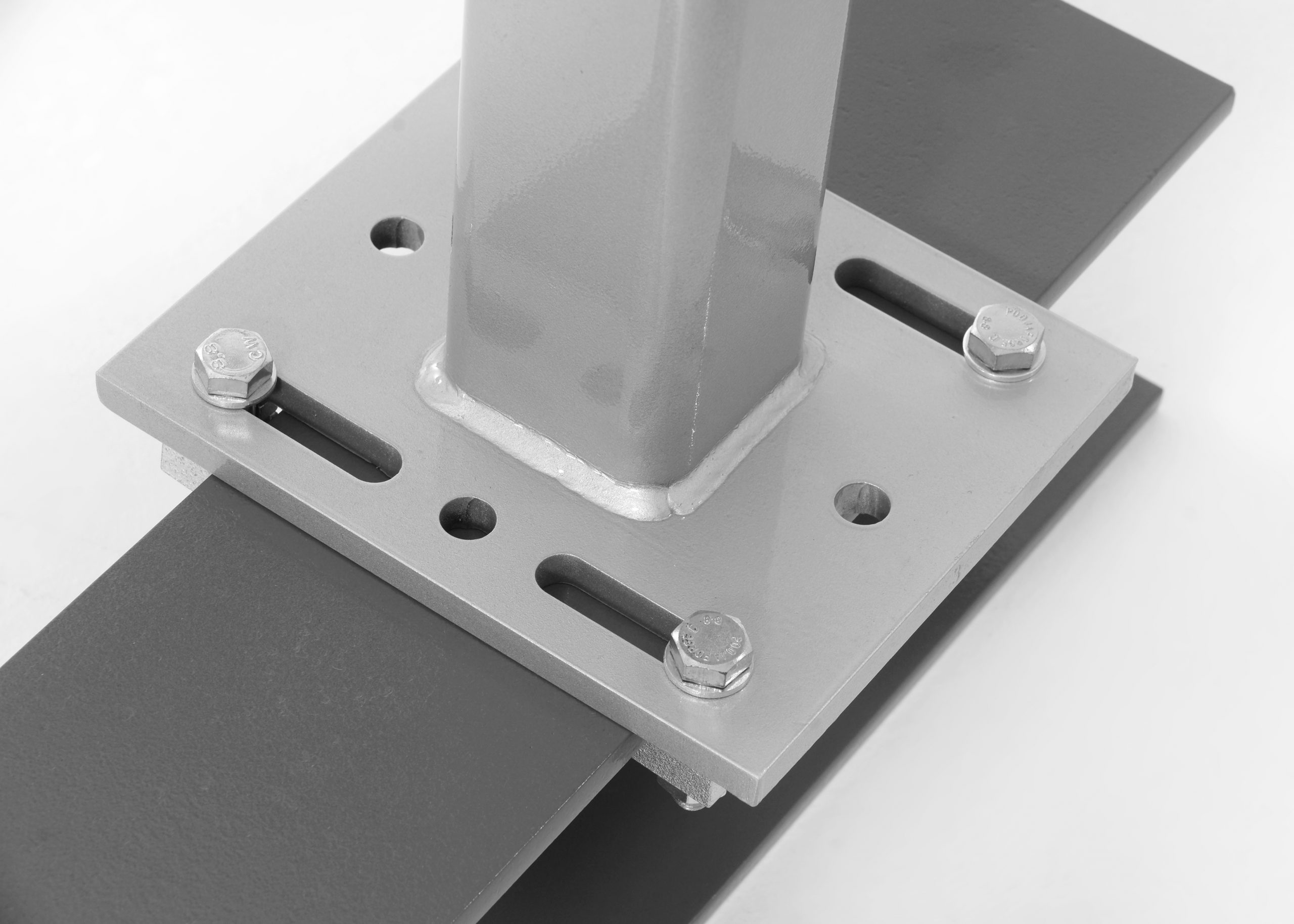

With the resource-saving use of torsionally stiff square tubes, MP-FLEX support structures achieve a weight saving of approx. 20 % compared to conventional steel structures made of double-T sections.

Due to customization, MP-FLEX mounts have no unnecessary holes and protrusions, unlike conventional modular systems.

The lower weight saves energy for production, transport and assembly.

The production sites in Germany and Austria ensure short transport routes, jobs and training places, availability and flexibility.

DIFFERENT SYSTEM SIZES

MP-FLEX support structures are available in various system sizes:

MP–FLEX–140 – takes very large loads

MP–FLEX–100 – for the most common applications

MP–FLEX–060 – for fastening of small and medium pipelines

All brackets and supports are available with mm accuracy

CONNECTION OPTIONS

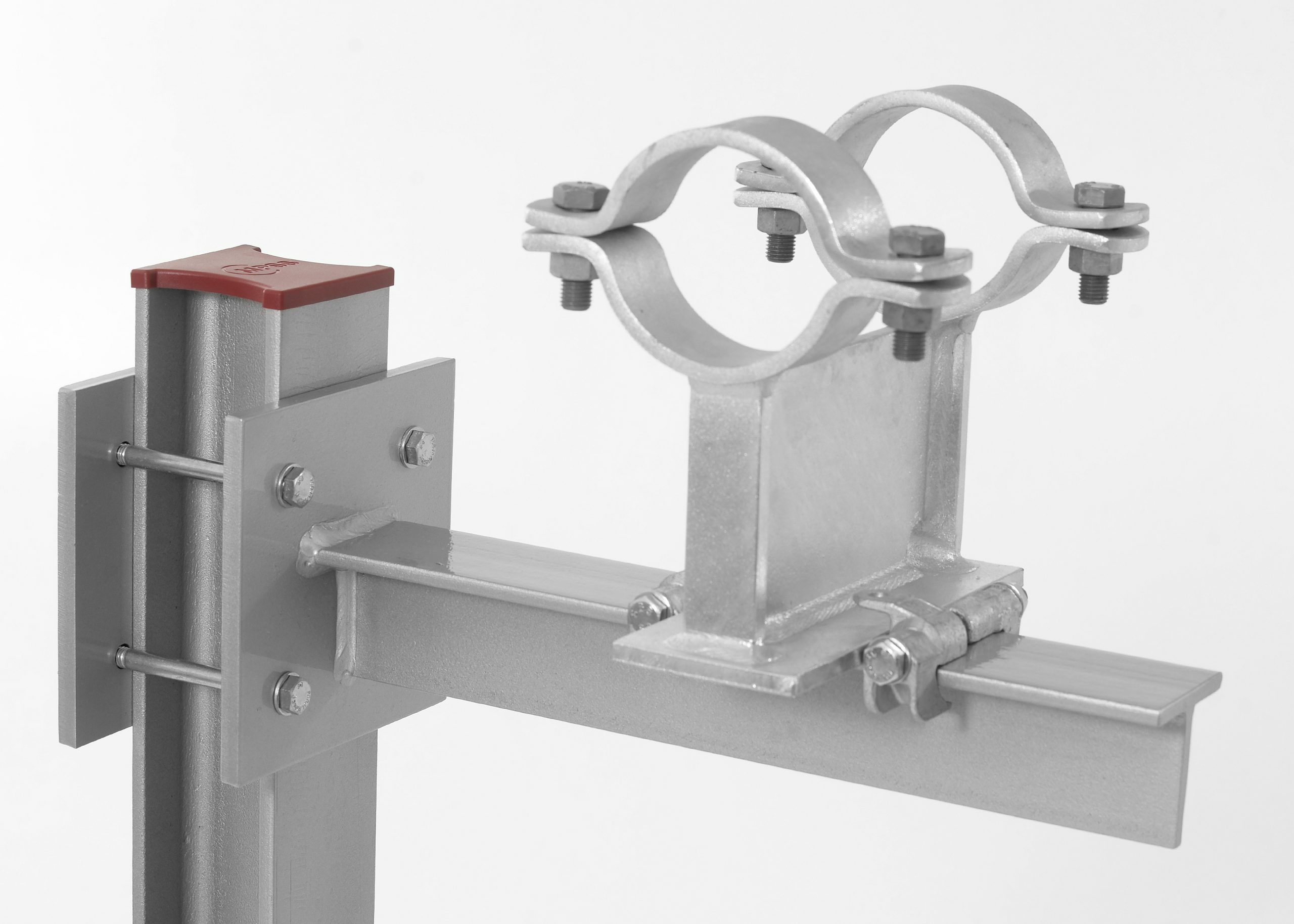

Bolted design – for high load capacity

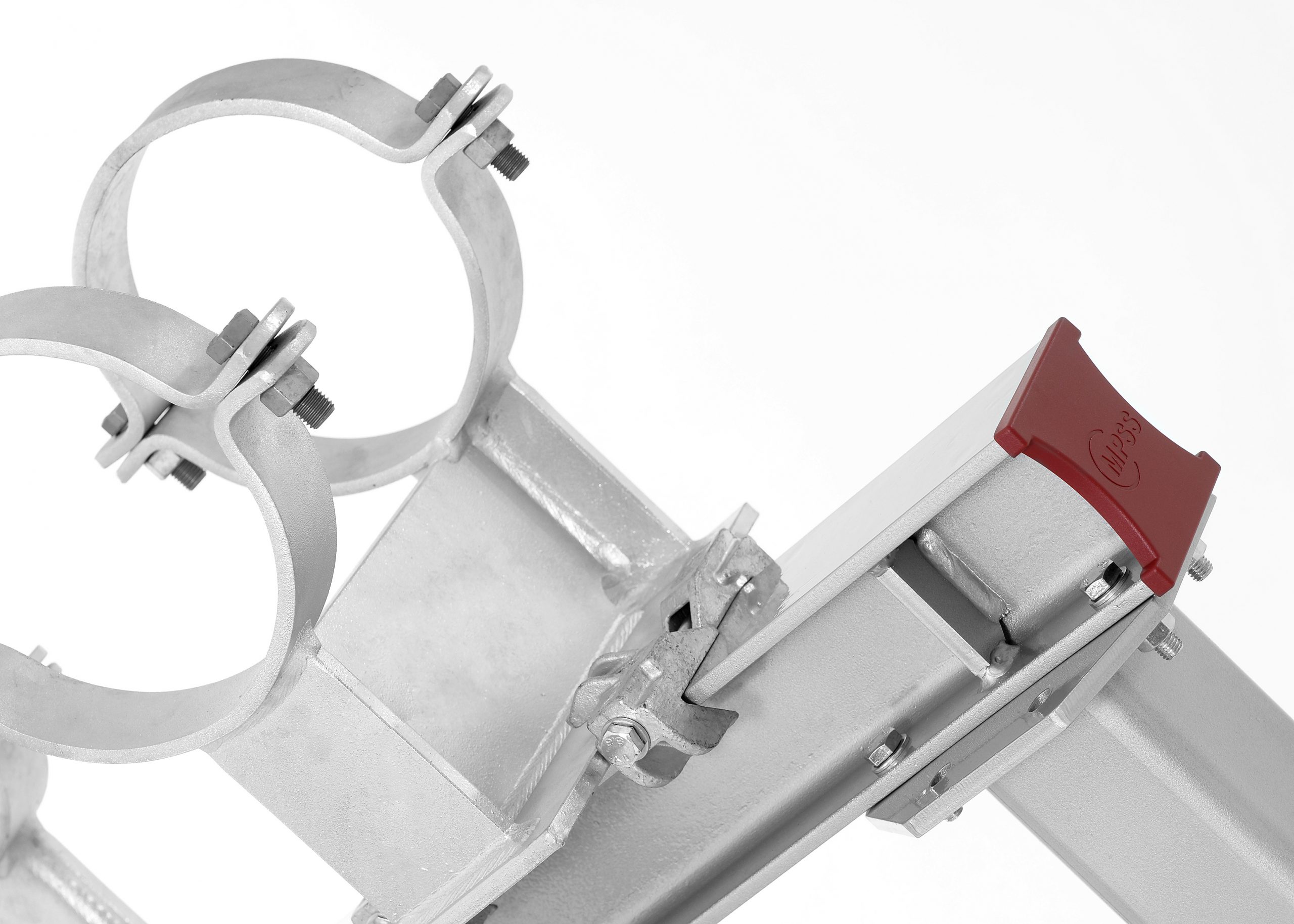

Clamped design – for stepless adjustability

SURFACE FINISH

Powder coated or hot dip galvanised finish.

The advantages of our mounting systems at a glance:

MP-FLEX-140 / MP-FLEX-100

MP-FLEX-060

PROVEN STABILITY

All MP-FLEX components and connections were designed and verified with RFEM according to Eurocode 3.

Verifiable structural calculations are available for over 6,000 bracket and size combinations.

If required, we can provide you with verifiable structural calculations according to Eurocode 3 for special constructions.

LIMITLESS POSSIBILITIES

More than 160 different components enable a precisely fitting solution for every mounting situation. The assemblies can be expanded as required and convince the user with unlimited planning freedom.

COMPATIBLE WITH OTHER SYSTEMS

Of course, MP-FLEX designs can also be combined with other support products.

DOWNLOAD MATERIAL FOR MP-FLEX

Here you can find download material for our MPSS mounting systems

MP-FLEX-140 application examples

MP-FLEX-100 application examples

MP-FLEX-060 application examples

The permissible loads for the individual MP-FLEX systems are available on request.